manual caja eaton fuller 13 velocidades

The Eaton Fuller 13-speed transmission is a robust and widely-used component in heavy-duty trucks, offering versatile gear ratios for varied hauling conditions.

Manual Eaton Fuller 13-velocidades systems are known for durability, requiring skilled operation and regular maintenance to prevent failures and optimize performance.

Troubleshooting often involves air line checks, diagnosing shift linkage issues, and addressing lubrication problems to ensure smooth and efficient operation.

Understanding the intricacies of these transmissions is crucial for mechanics and drivers alike, ensuring reliable transportation and minimizing downtime.

Proper shifting techniques and preventative maintenance are key to maximizing fuel efficiency and extending the lifespan of this complex mechanical system.

Overview of the Transmission

The Eaton Fuller 13-speed manual transmission represents a cornerstone of heavy-duty trucking, providing a broad spectrum of gear ratios for optimal performance across diverse terrains and load weights.

Designed for durability, these transmissions feature robust components capable of withstanding the stresses of commercial vehicle operation. The “13 velocidades” configuration allows drivers to precisely match engine speed to road conditions.

Its complex internal mechanisms, including main shafts, countershafts, and intricate gear sets, demand skilled operation and diligent maintenance. Proper lubrication and timely adjustments are vital for preventing failures and ensuring longevity.

Common applications include long-haul trucking, construction, and other demanding industries where reliability and efficiency are paramount.

Historical Context and Applications

Eaton Fuller transmissions have a long-standing history in the commercial vehicle industry, evolving alongside the demands of trucking and transportation. The 13-speed manual “caja” emerged as a solution for maximizing fuel efficiency and driver control.

Initially adopted for long-haul applications, these transmissions quickly became standard equipment in heavy-duty trucks. Their ability to handle significant torque and provide a wide range of gear ratios proved invaluable.

Over time, applications expanded to include construction, logging, and other industries requiring robust and reliable power transfer. The transmissions’ adaptability and durability cemented their position.

Today, while automated manual transmissions (AMTs) gain traction, the 13-speed manual remains prevalent, particularly where driver skill and direct control are prioritized.

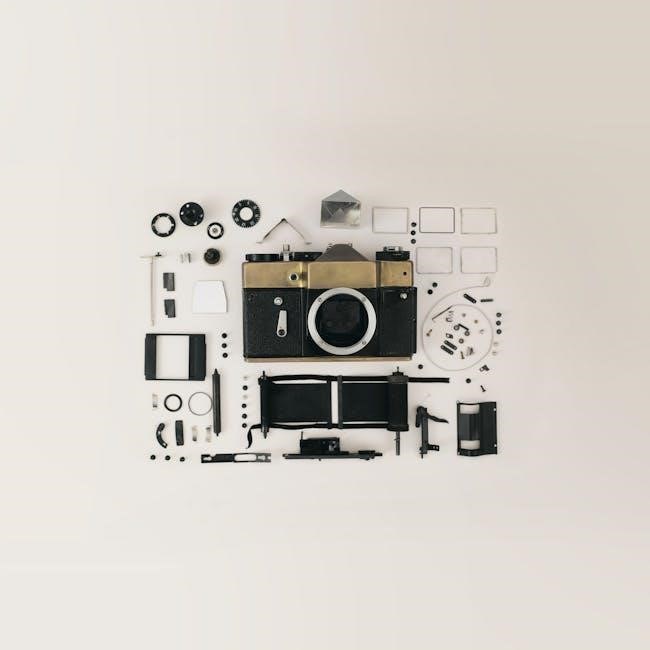

Understanding the Components

The Eaton Fuller 13-speed features a complex arrangement of gears, shafts, and synchronizers, working in harmony to deliver power efficiently.

Key components include the main shaft, countershaft, gear sets, and a sophisticated shifting mechanism, all crucial for operation.

Proper function relies on precise engagement and lubrication, ensuring smooth transitions between the numerous available gear ratios.

Main Shaft and Countershaft

The main shaft in an Eaton Fuller 13-speed transmission directly receives power from the engine, transmitting it to the output flange and ultimately, the drive wheels.

Its robust construction is vital for handling the high torque loads associated with heavy-duty trucking applications, ensuring reliable power delivery.

The countershaft, also known as the layshaft, plays a critical role in transferring power from the input shaft to the various gear sets.

It’s strategically positioned to facilitate the complex gear ratios inherent in a 13-speed configuration, enabling optimal performance across diverse terrains.

Precise alignment and bearing integrity of both shafts are paramount for minimizing friction and preventing premature wear, extending transmission life.

Damage to either shaft, often due to lubrication failure or excessive stress, can lead to significant operational issues and costly repairs.

Gear Sets and Ratios

Eaton Fuller 13-speed transmissions utilize a complex arrangement of gear sets to achieve a wide spectrum of ratios, optimizing engine performance for various driving conditions.

These ratios are meticulously calculated to provide both high starting torque for heavy loads and efficient cruising speeds on highways.

Multiple synchronized gearsets allow for smooth and efficient shifting between the numerous available speeds, enhancing driver comfort and reducing fatigue.

Gear damage, often manifesting as chipped or worn teeth, directly impacts shifting performance and can generate noticeable noise during operation.

Proper gear inspection during maintenance is crucial for identifying potential issues before they escalate into major transmission failures.

Understanding these ratios is key to maximizing fuel efficiency and minimizing wear and tear on the transmission components.

Synchronizers and Shifting Mechanism

The Eaton Fuller 13-speed transmission’s shifting mechanism relies heavily on synchronizers to match the speeds of the gears before engagement, ensuring smooth transitions.

These synchronizers utilize friction to equalize speeds, preventing grinding and minimizing wear on the gear teeth during shifts.

Shift linkage problems, including misalignment or worn components, can cause difficulty selecting gears or result in inaccurate shifts.

Proper adjustment of the shift linkage is critical for optimal performance and driver control.

Synchronizer replacement is often necessary when experiencing difficulty shifting into specific gears or encountering grinding noises.

Regular inspection and maintenance of the shifting mechanism are vital for preventing costly repairs and ensuring reliable operation.

Common Problems and Failures

Eaton Fuller 13-speed transmissions frequently experience issues like low oil levels, gear damage, and shift linkage problems, leading to operational difficulties.

Lubrication issues and worn components contribute to failures, requiring careful diagnosis and timely repairs to maintain functionality.

Identifying wear and tear on gears is crucial for preventing catastrophic breakdowns and ensuring long-term reliability.

Low Oil Level and Lubrication Issues

Maintaining proper oil levels within the Eaton Fuller 13-speed is paramount for its longevity. Running with insufficient lubrication causes accelerated wear on gears, bearings, and synchronizers, ultimately leading to costly failures.

Insufficient oil generates excessive heat, diminishing the oil’s protective qualities and promoting metal-to-metal contact. This is especially critical in high-stress applications and frequent shifting scenarios.

Leaks are a common source of low oil, requiring immediate attention; Regular inspections of seals and gaskets are essential. Using the correct oil type, specified by Eaton Fuller, is also vital for optimal performance and protection.

Consequences of neglecting lubrication include gear pitting, scoring, and eventual transmission failure, resulting in significant downtime and repair expenses.

Gear Damage: Identifying Wear and Tear

Detecting gear damage in a manual Eaton Fuller 13-speed transmission is crucial for preventing catastrophic failure. Look for signs like unusual noises – whining, grinding, or clicking – especially during specific gear engagements.

Visual inspection during maintenance reveals chipped, cracked, or worn gear teeth. Pitting, or small indentations, indicates surface fatigue and impending failure. Swelling of the gear teeth is also a critical sign.

Low speeds often amplify noises originating from damaged gears. Metal shavings in the oil are a definitive indicator of internal wear. Regular oil analysis can proactively identify early stages of gear deterioration.

Ignoring these warning signs leads to further damage, potentially requiring complete transmission replacement, incurring substantial costs and downtime.

Shift Linkage Problems and Adjustments

Shift linkage issues in a manual Eaton Fuller 13-speed often manifest as difficulty selecting gears, imprecise shifting, or gears popping out of engagement. These problems frequently stem from worn or loose linkage components.

Adjustments are critical; proper alignment ensures the shift lever accurately engages the shift forks within the transmission. Incorrect adjustment can cause binding or incomplete gear selection.

Inspect the linkage rods, bushings, and pivot points for wear, damage, or looseness. Replacing worn components is often necessary. Air line connections impacting the shift system must also be verified.

Precise adjustments, following the manufacturer’s specifications, are vital for smooth, reliable shifting and preventing further damage to the transmission’s internal components.

Diagnostic Procedures

Diagnosing a manual Eaton Fuller 13-velocidades involves identifying noises, checking for fluid leaks, and utilizing diagnostic tools for accurate assessment.

Analyzing vibrations and unusual sounds helps pinpoint internal issues, while leak detection reveals potential seal or housing problems.

Comprehensive testing ensures proper functionality and guides effective repair strategies for this complex transmission system.

Identifying Noises and Vibrations

Accurately pinpointing noises and vibrations within a manual Eaton Fuller 13-velocidades transmission is crucial for effective diagnosis. Low-speed noises, particularly grinding or whining sounds, often indicate gear wear or damage.

Higher-pitched sounds can stem from bearing failures, while rhythmic vibrations frequently suggest imbalances or misaligned components.

Pay close attention to when these noises occur – during shifting, acceleration, deceleration, or while in specific gears.

Detailed observation, coupled with a systematic approach, allows technicians to isolate the source of the problem, guiding them towards appropriate repair procedures and preventing further damage.

Remember that unusual noises or vibrations are rarely normal and warrant immediate investigation.

Checking for Fluid Leaks

Regularly inspecting a manual Eaton Fuller 13-velocidades transmission for fluid leaks is paramount for maintaining optimal performance and preventing catastrophic failure. Leaks often originate from seals – particularly the rear transmission seal – a common issue.

Carefully examine the transmission casing, input and output shafts, and around the shift linkage for any signs of oil residue.

Pay attention to the quantity and color of the fluid; a significant loss or unusual discoloration indicates a serious problem.

Promptly address any leaks, as low fluid levels lead to increased friction, heat, and ultimately, component damage.

Consistent monitoring and timely repairs are essential for extending the transmission’s lifespan.

Using Diagnostic Tools

Diagnosing issues within a manual Eaton Fuller 13-velocidades transmission often requires specialized tools beyond basic visual inspections. A thorough diagnostic approach is crucial for accurate identification of problems.

Pressure gauges are essential for verifying proper air pressure within the shift system, crucial for smooth gear changes.

Scan tools, when applicable to AutoShift variants, can reveal fault codes providing valuable clues about internal malfunctions.

Listening devices, like stethoscopes, help pinpoint unusual noises originating from specific gear sets or bearings.

Proper utilization of these tools, combined with technical expertise, ensures effective troubleshooting and repair.

Repair and Maintenance

Regular maintenance of the manual Eaton Fuller 13-velocidades is vital, including oil changes, synchronizer checks, and gear inspections for optimal performance.

Prompt repairs address issues like gear damage or shift linkage problems, preventing further complications and ensuring reliable operation.

Skilled technicians are essential for accurate diagnosis and effective execution of repair procedures, maximizing transmission lifespan.

Transmission Oil Change Procedures

Performing a transmission oil change on a manual Eaton Fuller 13-velocidades requires careful attention to detail. Begin by ensuring the transmission is adequately cooled, avoiding burns. Drain the old oil completely, utilizing the drain plug located on the transmission housing.

Inspect the drained oil for metal shavings, indicating potential internal wear. Replace the oil filter with a new, high-quality filter designed for the Eaton Fuller transmission.

Refill the transmission with the manufacturer-recommended oil type and quantity, typically a heavy-duty gear oil. Check the oil level using the dipstick, ensuring it falls within the specified range. Finally, verify for leaks after a short test run.

Synchronizer Replacement

Replacing synchronizers in a manual Eaton Fuller 13-velocidades transmission is a complex procedure demanding precision. Begin by draining the transmission oil and removing the top cover to access the internal components. Carefully extract the damaged synchronizer, noting its orientation and associated parts.

Thoroughly inspect the mating surfaces for wear or damage, addressing any issues before installing the new synchronizer. Lubricate the new synchronizer with transmission oil before installation.

Reassemble the transmission, ensuring proper alignment and torque specifications. Finally, refill with the correct oil and test the shifting performance to confirm successful repair.

Gear Replacement and Inspection

Gear replacement within a manual Eaton Fuller 13-velocidades transmission requires meticulous attention. Begin by removing the side cover and carefully extracting the damaged gear, documenting its position for reassembly. Thoroughly inspect all other gears for signs of wear, pitting, or broken teeth.

Check the corresponding shafts and bearings for damage, replacing them as needed. Lubricate the new gear and shaft assembly with transmission oil before installation.

Reassemble the transmission, adhering to precise torque specifications, and verify proper gear mesh before final closure.

Air System Troubleshooting

Air line connections are vital for the manual Eaton Fuller 13-velocidades. Testing air pressure and diagnosing shift issues are crucial for proper operation.

Ensure correct functionality of the air system to avoid shifting problems and maintain optimal performance.

Air Line Connections and Function

The air system in a manual Eaton Fuller 13-velocidades transmission is critical for smooth and reliable shifting. Proper connections and functionality are paramount. Air lines deliver compressed air to the shift cylinders, enabling gear changes.

Inspect all connections for leaks, ensuring they are secure and free from damage. Verify the air supply pressure meets the manufacturer’s specifications. Incorrect pressure can cause shifting difficulties or failure.

Pay close attention to the lines connecting the air governor, shift control valve, and the transmission itself; A malfunctioning air system directly impacts the transmission’s ability to select the correct gear.

Air Pressure Testing

Air pressure testing is vital for diagnosing issues within the manual Eaton Fuller 13-velocidades transmission’s pneumatic system. Begin by verifying the air compressor output, ensuring it reaches the specified PSI. Utilize a gauge to check pressure at various points – the air governor, shift control valve, and directly at the transmission.

Look for pressure drops indicating leaks in air lines or internal components. A consistent, stable pressure reading confirms system integrity. Low pressure can cause sluggish shifting or complete failure to engage gears.

Remember to test during both static and dynamic conditions, simulating real-world operation.

Troubleshooting Air Shift Issues

Troubleshooting air shift issues in a manual Eaton Fuller 13-velocidades transmission often begins with verifying proper air pressure and line connections. Inspect for leaks in air lines, fittings, and the shift control valve. Check the air governor for correct operation, ensuring it regulates pressure effectively.

If shifting is delayed or erratic, examine the shift linkage for binding or misalignment. A faulty shift solenoid can also cause problems; testing its functionality is crucial. Manual adjustments may be needed.

Remember to consult the service manual for specific diagnostic procedures and component locations.

Shifting Techniques and Best Practices

Mastering the manual caja Eaton Fuller 13 velocidades requires precise clutch control, coordinated movements, and understanding gear selection for optimal performance.

Avoid abrupt shifts and excessive RPMs to prolong component life and maximize fuel efficiency, utilizing smooth transitions between gears.

Proper technique minimizes wear and tear, ensuring reliable operation and reducing the risk of costly repairs.

Proper Shifting Procedures for 13-Speed Transmissions

Operating a manual caja Eaton Fuller 13 velocidades demands a specific sequence. Begin by depressing the clutch pedal fully and selecting the appropriate low-range gear.

Synchronize engine speed with the target gear by gently releasing the clutch while applying throttle.

Transitioning to higher gears involves a similar process, ensuring smooth engagement and avoiding gear clash.

Utilize the range shift lever to move between low and high ranges, coordinating it with gear selection;

Downshifting requires anticipating speed changes and selecting a lower gear to maintain control and engine braking.

Remember to fully depress the clutch during each shift, preventing damage to the synchronizers and gears.

Practice makes perfect; mastering these procedures ensures efficient and reliable operation.

Avoiding Common Shifting Mistakes

With a manual caja Eaton Fuller 13 velocidades, avoid “floating” – shifting without fully depressing the clutch, causing gear damage.

Never force a shift; if resistance is felt, re-attempt synchronization with engine speed.

Resist the urge to skip gears, especially during downshifting, to prevent excessive stress on components.

Don’t ride the clutch, as this generates heat and accelerates wear.

Incorrect range selection can lead to mismatched gear ratios and inefficient operation.

Ignoring engine RPMs during shifts results in jerky movements and potential damage.

Consistent practice and awareness of these pitfalls will prolong transmission life and improve driving experience.

Optimizing Fuel Efficiency Through Shifting

For a manual caja Eaton Fuller 13 velocidades, prioritize higher gears whenever possible, maintaining optimal engine RPMs for fuel conservation.

Anticipate road conditions and shift proactively to avoid unnecessary braking and acceleration, maximizing momentum.

Utilize the full range of gears, avoiding prolonged operation in inefficient ranges.

Smooth and deliberate shifting minimizes power loss and enhances fuel economy.

Avoid excessive idling, as it consumes fuel without covering distance.

Master progressive shifting, gradually increasing speed through gears, rather than abrupt changes.

Consistent application of these techniques yields significant fuel savings over time.

Advanced Troubleshooting

Complex manual caja Eaton Fuller 13 velocidades issues require specialized diagnostic tools and a deep understanding of internal components.

AutoShift systems demand specific software and expertise for accurate fault identification and resolution.

Internal failures often necessitate complete transmission disassembly for thorough inspection and repair.

Diagnosing Internal Transmission Failures

Internal failures within a manual caja Eaton Fuller 13 velocidades often present as significant noise, vibration, or complete loss of drive. A meticulous teardown is crucial, beginning with draining the transmission fluid and inspecting for metallic debris – a clear indicator of gear damage.

Carefully examine gear teeth for pitting, wear, or breakage, paying close attention to the synchronizer components. Look for signs of overheating, such as discolored or brittle components.

Inspect the main shaft and countershaft for bending or damage.

Detailed analysis of the wear patterns can pinpoint the origin of the failure, guiding the repair process and preventing recurrence. Proper documentation throughout the process is essential.

Understanding AutoShift System Diagnostics

While focusing on manual caja Eaton Fuller 13 velocidades, understanding AutoShift diagnostics is valuable as many utilize similar core components. Diagnostic procedures involve utilizing specialized software to retrieve fault codes, revealing issues within the electronic control unit (ECU) or associated sensors.

Common codes relate to air pressure inconsistencies, solenoid malfunctions, or communication errors.

Analyzing these codes requires a thorough understanding of the system’s wiring diagrams and operational logic.

Careful examination of sensor readings and actuator performance is vital, often requiring a multimeter and oscilloscope for accurate assessment.

Proper interpretation of diagnostic data ensures targeted repairs and minimizes unnecessary component replacement.

Identifying and Resolving Complex Issues

Addressing complex problems in a manual caja Eaton Fuller 13 velocidades often requires a systematic approach beyond basic diagnostics. Internal failures, like broken gears or damaged synchronizers, necessitate a complete transmission teardown for inspection.

Identifying the root cause demands meticulous examination of wear patterns and fracture surfaces.

Intermittent issues, such as slipping gears or difficulty shifting, can stem from worn shift linkage or internal clutch pack problems.

Resolving these requires precise adjustments and component replacement.

Thorough testing post-repair is crucial to confirm proper functionality and prevent recurrence of the issue.